Manufacturing process

Koishiwara pottery

Koishiwara pottery has establised "yo no bi" (beauty of use) with settling as daily tableware. The craftmanship of "Tobikanna", "Hakeme", "Kushime". "Yubikaki", "Nagashikake", and "Uchikake" brings out the simple and warm characteristic. Those potteries hope for further development with cafully carrying on the craftmanship and technique.

Takatori pottery

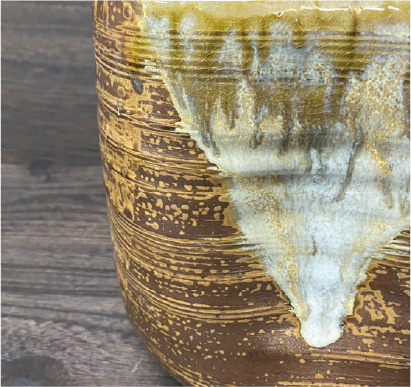

In Toho Village, there are several potteries that have inherited the Takatori-pottery technique, and they are developing the world of kirei-sabi (cleanliness and simplicity), passing on the style of Enshu Takatori to the present. The elaborate process, the gorgeous glaze, the delicate texture. In particular, tea ware made from iron, straw ashes, and wood ashes, fired with delicately mixed glazes, is full of elegance.

Making the pottery clay

They make the pottery clay with brown and white rocks from Koishiwara district. After drying those rocks, they crush rocks with the grinder.

Forming pottery shape

They knead the clay more than 50 times. The process is called "Kiku-neri" kneading because it is done in the shape of chyrysanthemun petals. It is formed by turning a rotating stand made of zelkova wood.

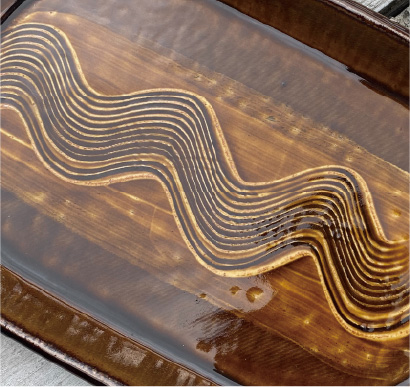

Decorative techniques

There are traditional techniques unique to Koishiwara pottery such as "Tobikanna","Kushime", and "Hakeme". As well as the glaze what made from a mixture of straw ashes and wood ashes from the local area can be poured over the plate while the wheel is slowly rotating, or little by little.

Koishiwara pottery

-

Tobikanna

patterns made with a curved plane

Kushime

patterns made with a comb-

shaped tool

Yubikaki

patterns made with fingers

Kakiotoshi

patterns drawn by scraping off the surface

Shinogi

ridge-like patterns created with a spatula

Sansai

patterns as three different colors by glaze

Ponkaki

patterns made with a curved plane while rotating the wheel.

Nagashikake

patterns poured glaze at even intervals

Hakeme

patterns created lines by brush marks

Uchikake

paterns sprinkling glaze little by little as if striking it

Senhori

patterns carved lines with a pointed tool

Mentori

patterns created a polyhedron by scraping

Zougan

patterns inlayed the clay with a different color

Takatori pottery

-

Usuzukuri

a thin vessel

-

Mentori

patterns shaved by Enshu Kirigata

-

Maeoshi

patterns dented the front by pressing

-

Tojime

patterns overlapped binding

-

Kushime

patterns made with a comb-

shaped tool -

Sukashibori

patterns as embossing

-

Kakewake

applying different colors of glaze

-

Nagashikake

patterns poured glaze predicting the view after firing

Glazing

Glazing is the process of applying a glaze. The last step before firing. During firing, the glaze melts at high temperatures and becomes glassy on the surface of the ware.

Firing

Firing is done using a climbing kiln. When the temperature reaches 1,000 ℃ in about half a day (13-14 hours), the kiln enters the process of horizontal firing. After reaching 1000 ℃ , the kiln is fired for about 30 hours. After firing, the kiln is cooled down for a few days, and then it is removed from the kiln.